Welding Rod Sizes Smallest To Largest

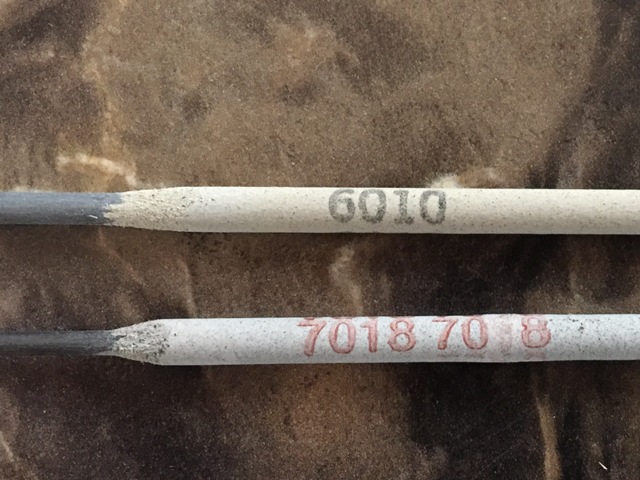

Welding rods are of different types with the most common welding rod sizes being the 6010 6011 6012 6013 7014 7024 7018.

Welding rod sizes smallest to largest. Double click on chart to view quick guide for selecting mig wire size and welder amperage for your application. Mig welding wire tig tungsten tig filler rods welding electrodes. Tig welding parametres table. A bad low quality earth or a low voltage supply can seriously lower the maximum welding capabilities of your welder.

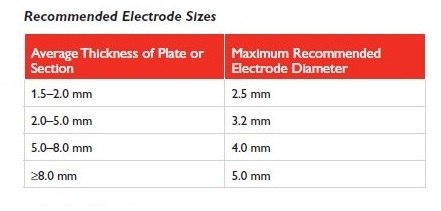

Mig welding wire selection chart. The thicker the rod the higher your amperage rating has to be. The length usually ranges between 12 and 18. Welding rod sizing chart the rod sizes available are 1 8 5 32 and 3 16.

Concrete is strong under compression but has weak tensile strength rebar significantly increases the tensile strength of the. Due to high demand you may experience longer than normal response times when calling or emailing. The third digit represents the position in which you can use the rod. Usp is open shipping orders.

70 for example implies that the electrode has a tensile strength of 70 000 pounds per square inch. Rebar short for reinforcing bar known when massed as reinforcing steel or reinforcement steel is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. So here are a few guidelines for choosing the best size filler rod. Let s learn in details with uses.

The first two numbers on the size number of the electrode usually represent the tensile strength of the electrode. Thus if you need to weld thin metal sheets you should also prefer thin welding rods. A recap on welding rod classification. Let s take a closer look at the 7018 6013 6011 and 6010 welding rods four of the most common and fundamental welding rod sizes which you re likely to come across to try to understand each in more detail.

We are working hard to serve our customers while keeping our team safe and healthy. Typical rod sizes are 5 64 1 16 1 8 3 32 5 32 3 16 7 32 1 4 and 5 16 inch. Generally speaking using filler metal slightly thinner that what is being welded works best. For sheet metal thicknesses 1 8 3 2mm and under rod size should not be thicker than the metal being welded.